JENNINGS INTERNATIONAL CORPORATION, USA

- Home

- Partners

Kemtech is proud to be associated with JENNINGS INTERNATIONAL CORPORATION who are the world leaders in supply of PTFE Fine Power Paste Extrusion machinery solutions.

JENNINGS INTERNATIONAL are manufacturers of quality PTFE Fine Powder Paste Extrusion equipment since 1953. Jennings has a state of the art machining and fabrication facility. When combined with designs which have proven themselves over the years, we have a winning formula which allows a high degree of control over the manufacturing process, and thus the quality of the final product. Over 95% of our machined and fabricated parts are produced in house by Jennings. This allows us to offer industry leading quality.

Our success has allowed us to reinvest in new equipment which further enhances the quality of our parts and manufacturing processes. To complement our existing CNC Department, Jennings has recently added a state of the art Mitsubishi Laser for the processing of sheet and light plate, as well as a Mazak Vertical Machining Center, which is capable of machining platens up to 55" by 79". This equipment allows unsurpassed precision in sheet metal fabrication and machining.

Because of the quality of our designs, many of our machines have been in service for decades. Our customers have welcomed our machine Re-Manufacturing program with great enthusiasm. We can bring your machine up to current specifications, incorporating state of the art features such as computer control and our touch screen console.

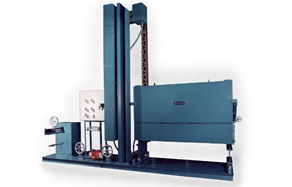

PTFE Paste Extrusion is a batch process. The product yield is directly related to the stroke length of the Extruder. Jennings offers the longest stroke Extruders on the world market at 120", approximately 3 meters. Therefore, Jennings offers the longest product yields per extrusion run. Jennings also pays particular attention to the control of the Extrusion speed which is directly related to the quality of the end product. Jennings has a state of the art oven system to maximize the speed of the Extrusion.

Jennings has many many times more number of PTFE FPP Line extruders installations worldwide then any other company.

Being a PTFE Fine Powder Paste Extrusion solutions specialist. More than 95% of Jennings customers have more than one Jennings Extruder, and the largest PTFE Wire manufacturer in the world owns more than 40 Jennings Extruders. This is testament to the quality that Jennings builds into the equipment.

Needless to say Jennings has been and continues to be the world leader in the design and manufacture of PTFE Ram Extruders. We have over 600 Jennings machines in service around the world producing such products as PTFE insulated wire, micro tubing, medical tubing, large bore tubing, push-pull cable tubing, PTFE Film etc. Jennings produces reliable, time proven machinery which is ideal for your application. Jennings have many fine powder resin manufacturers who currently operate Jennings extruders in their laboratories to test their products.

These manufacturers include:- Asahi Glass Flouropolymers USA, Inc.

- Gujarat Fluorochemicals Ltd.

- Daikin America, Inc.

- Solvay

- Dupont

- Dyneon

You may be pleased to note that Jennings horizontal extruders come in standard sizes of 25-Ton, 50-Ton, 75-Ton, and 100-Tons of thrust, with stroke lengths of 36", 54", 72",108" and 120". This allows productivity unmatched in the industry. Jennings horizontal units are used in such applications as medical tubing and wire coating etc. With the addition of a 48" vaporizing console, they are also used for push-pull cable tubing.

Jennings' most popular model is the #18108 50-Ton 108" Stroke extruder. It gives the World's Highest yield per cycle and when combined with Jennings other equipment, makes the perfect extruder for a wire line or tubing line.

We encourage you to explore our new and exciting innovations. To our potential customers, we welcome you to learn about the many benefits to the products await you as below.

Jennings Product Range

- PTFE Horizontal Extruders: Available in standard sizes of 25-Ton, 50-Ton, 75-Ton, and 100-Tons of thrust, with stroke lengths of 36", 54", 72", 108" and (the world’s longest stroke extruder) 120” allowing productivity unmatched in the industry.

- PTFE Vertical Extruders: Equipment ranging from 7.5-Tons up to 100-Tons of thrust and with stroke lengths of 36” and 54”.

- PTFE Film/Tape Extrusion Lines: For Web thickness as thin as 0.002” made from specially designed Fan Dies to produce a product out of the die 12” (300mm) wide and 0.040” (1mm) thick.

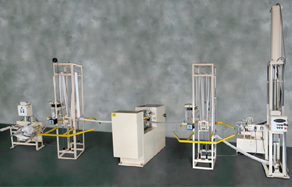

- PTFE Wire Insulating Lines:Hydraulically powered PFTE Wire Insulating Line extruding at speeds of up to 350 ft/minute with continuous yields exceeding up to 25,000 Ft/machine load. Extruders with Ram strokes in 48”, 72” & 108”.

- PTFE Vaporising Console: In both 24" and 48" capstan wheel sizes. With improved technique of volatising the perform lubricant to a degree which allows to advance production speeds to 350 ft/minute even for the high speed production of tubing for the push/pull cable industry.

- ASTM Test Extruders: A 10-Ton Test Extruder per the PTFE processing specifications identified in ASTM D-4895-4; Standard Specification for Polytetrafluoroethylene (PTFE) Resin Produced from Dispersion. Having a preform diameter of 32mm and preform length of 300mm. Ram speed is accurately controlled over the range of 15 to 25mm/min and specifically controlled to 18mm/min during extrusion.

- Touch Screen Control: Operator Interface software (or HMI software) has replaced the old push button console with digital controls and displays.

Applications and Markets Served:

- Horizontal Extruders: for medical tubing, wire coating and push/pull cable tubing used to produce Industrial Tubing, Aerospace Hose, Automotive Hose, Medical Tubing, Cables, Communication Cables, RG Cables, Sheet/Film/Tape Products, etc.

- Vertical Extruders: for micro-tubing and medical tubing, to large bore tubing and film used to produce Industrial Tubing, Aerospace Hose, Automotive Hose, Medical Tubing, Cables, Communication Cables, RG Cables, Sheet/Film/Tape Products, etc.

- PTFE Film/Tape Extrusion Lines: Filtration Membranes, Gaskets, Tape Wrapping, Dental Floss, Very Low Density Thread Seal Tape, High Tensile Thread and Dielectric Film Applications.

- Wire Insulating Lines:Cables, Communication Cables, Aerospace Cables, RG Cables, etc.

- Vaporizing Console: quickest possible curing of PTFE extruded products

Products Gallery

Media

- "CABLE & WIRE FAIR 2017 NEWS LETTER – Interview of Kemtech’s MD"

October 2017 - "WIRE NEWS 2016"

September 2016 - "WIRE & TUBE 2016 Dusseldorf"

April 2016 - KIESELSTEIN With New Representative for Indian Market

October 2014 - KIESELSTEIN announces cooperation with new representative for the Indian market

September 29, 2014

Contact Us

-

Kemtech International Private Ltd.

505-506 Red Rose

49-50 Nehru Place

New Delhi 110019 INDIA - Phone No.: +91 11 41881341

- Fax No.: +91 11 26468345

- Email: info@kemtech.in

-

Monday - Saturday: 9:30 am - 06:00 pm

2nd & 4th Saturday: Non-Working Days