Jouhsen-bündgens Maschinenbau GmbH, Germany

- Home

- Partners

Expert for wire processing machinery High-precision machine engineering with decades of experience – that is what Jouhsen Bundgens stands for. The global player successfully focuses on wire processing machines. With Jouhsen Bundgens production boils down to a simple formula: Precision + Speed = Efficiency.

Thanks to its engineering know-how and sound German expertise Jouhsen Bundgens realises custom-made solutions for many different fields of application with the utmost precision – be it medical equipment, roller bearings or consumer products – our highly qualified team explores and grasps every aspect of the respective processes.

The result: reliable machines tailored to your needs. With these machines you can:

- Process wires with a diameter of 0.02 to 16 mm.

- Manufacture parts out of wires with a length of 2 mm to infinite

You can always expect tailor-made solutions that enable fast, precise and efficient manufacturing.

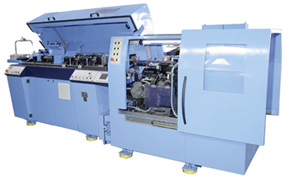

JOUHSEN PRODUCT RANGE

- Straigthening and Cutting: Axles, shafts, needles, cannulae, pins: It all starts with wire or tubing from a ring or coil.

- Electro Fisson: An efficient high-precision process to cut wires and tubing burr-free.

- End Machining: To manufacture geometrically shaped ends such as chamfers, radii, recesses or grooves at high-speed and with maximum precision.

- Cold Forming: The efficent possibility to combine several processes such as straightening, cutting or subsequent processing as point grinding.

- Point Grinding: Precise, fast & effective to process needle blanks made of wire with a strength of 0.4 to 1.3 mm

Applications and Markets Served:

- Automotive: With machinery by Jouhsen Bundgens you can produce bolts, axles or engine shafts for automotive parts in large quantities and with maximum precision.

- Batteries:Special pins or nickel-plated pins in a uniform global quality with a high output – production efficiency by Jouhsen-buendgens

- Cannulae: Fast production of cannulae with automatic sorting and magazining

- Dental Equipment: High-precision straightening, cutting and grinding of dental drill bits.

- Drive Chains & Cam Chains: Jouhsen-buendgens machines can process steel or stainless steel with maximum precision at high efficiency.

- Electronic Components & Microparts: Include plug pins, contact pins, sockets, feedthroughs and diode pins, among others, which may be made of coated special materials, non-ferrous metals, gold or silver, partly have very small diameters.

- Furniture: Efficient production of fittings and door pins for furniture. Process steel and stainless steel and produce in a precise and straight manner – without damaging the surface.

- Lancets: Solutions by Jouhsen-buendgens for your round-the-clock production and damage-free wire processing – two key aspects of manufacturing lancet blanks.

- Lighting Engineering: Efficient production of electrodes, holders & pins for lighting engineering

- Medical Needles: Bending, grinding and laser drilling: three processes that are important for the production of medical needles – one solution for a sucessful production: Jouhsen-buendgens

- Roller Bearings: Great precision – with a maximum output. With machinery by Jouhsen Bundgens you can produce up to 2,000 units per minute.

- Watches: Extraordinary precision: This is a crucial requirement for manufacturing shafts, axles and pins for clocks and watches. And this requires a high level of dimensional accuracy.

Products Gallery

Media

- "CABLE & WIRE FAIR 2017 NEWS LETTER – Interview of Kemtech’s MD"

October 2017 - "WIRE NEWS 2016"

September 2016 - "WIRE & TUBE 2016 Dusseldorf"

April 2016 - KIESELSTEIN With New Representative for Indian Market

October 2014 - KIESELSTEIN announces cooperation with new representative for the Indian market

September 29, 2014

Contact Us

-

Kemtech International Private Ltd.

505-506 Red Rose

49-50 Nehru Place

New Delhi 110019 INDIA - Phone No.: +91 11 41881341

- Fax No.: +91 11 26468345

- Email: info@kemtech.in

-

Monday - Saturday: 9:30 am - 06:00 pm

2nd & 4th Saturday: Non-Working Days